Measures Against Vibration and Shock

--- About vibration during transportation ---

Though there is no precise definition to describe the high frequency rate for vibration,

it is said that the rate is higher than 20Hz (1Hz =1vibration/1sec), and the high frequency can’t be prevented by the truck’s air suspension system.

Please see this video for the ZERO G series, a packaging material designed to be anti-vibration.

☟

--- Shocking scene caused by vibration during transportation---

■The products are damaged by vibration and shock in various occasions during the transportation as shown on the slides on the right side.

・On the collapse or unevenness of road surfaces during truck transportation

・Shock on products at loading time

・The switching and the connecting parts of railroad during cargo transportation

・At the time of departing, landing, and loading during air transportation

・Cargo handling by forklift at the container yard

・Cargo handling by forklift at the packaging

--- Cases of Corruption by Vibration and Shock During Transportation ---

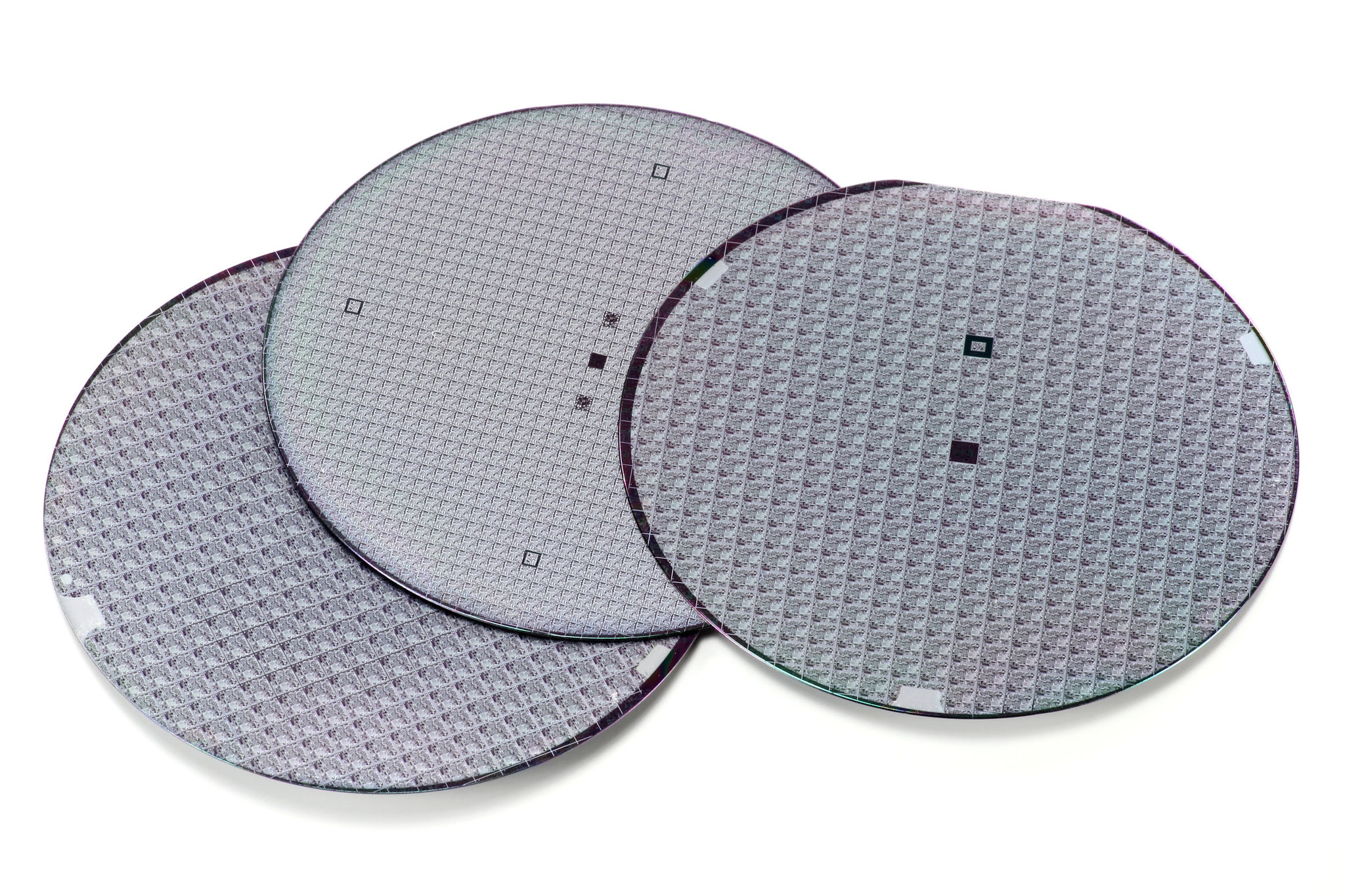

■The products shown on the left slides show the corruption caused by vibration and shock during the transportation.

・Damage on precision instrument parts

・Cracked pipe

・Crack on details of the products

・Prints peeled off

・Disconnected connector

・Damage on green goods

・Crushed cake

--- Vibration on the Loading Platform of Trucks ---

■The Unpreventable Vibration Even by Air Suspension of Trucks

The loading platform of a truck is subject to vibration as it travels over the frame of the truck with the engine always rotating during transport.The suspension of the chassis may prevent vibration and impacts passing through the road, but it does not prevent vibrations and impacts transmitted by high frequencies through the engine to the loading platform.

--- Anti-Vibration Pallets ---

■Features in Steel Anti-Vibration Pallets

・Enabling to provide better vibration control than truck air-suspension

・Using superb materials in anti-vibration and durable ether-based polyurethane foam

・Selecting appropriate materials according the products’ weight to keep the stable effectiveness

・Able to make custom sizes for fitting products in various sizes

・Superior in durability

■Features in Wood Anti-Vibration Pallets

・Enabling to provide better vibration control than truck air-suspension

・Using excellent vibration control material and ether-polyurethane foam superb in durability

・Choose the right cushion materials based on the weight of the product to maintain a stable effect.

・Able to make custom-made sizes for products of different sizes

・The low fare makes it suitable for one way transport.

※The Anti-vibration pallet is a product jointly developed by Nabeya co., LTD and Musashi Trade Transport Co., Ltd.

■Feature of Ether-based Polyurethane Foam Anti-Vibration Material

・Corresponds to the attenuation and shock absorption of continuous vibration

・Attenuates at low frequency vibration

・Enable to minimize creep deformation(deformation with age)

・More than 20 types of materials that can withstand high-stress and vibration

・Over 30 years of experience and solid reliability

・Excellent durability and longevity

--- Air-Suspension Car vs Anti-Vibration Palette Comparison ---

■Performance Verification in Anti-Vibration Palette

・An actual vehicle running test of a car equipped with Anti-Vibration palette was conducted.

・In the actual vehicle running test with Anti-vibration, it was verified that it reduced 21HZ high- frequency vibration compared to air-suspension vehicle.

・Enable to suppress vibration and shock superior to air-suspension vehicle.

・Please refer to the result of the actual running test shown below.

--- Comparison in High-Frequency Rate : Air-Suspension vehicle vs Anti-Vibration Vehicle ---

・The loaded platform of air suspension heavy-duty vehicle

| Speed km/h | 90km/h | 80km/h | 70km/h |

| Engine RPM | 1410 | 1280 | 1110 |

| Frequency | 24Hz | 21Hz | 18Hz |

Attenuation is about 91.4% (below 1/10)

・Case with Anti-Vibration palette

| Frequency | 2.4Hz | 2.1Hz | 1.8Hz |

--- Actual Vehicle Running Test ---

※Below is the joint verification test with Nabeya co.,Ltd and Musashi Trading Co., Ltd

To confirm the effectiveness of Anti-Vibration palette, we ran a truck equipped with Anti-Vibration palette (pad type) equipped with dummy weights and obtained the vibration level data of the upper and lower pallets.

■Sample

・Palette:1100x1100mm (made of steel)

・Anti-Vibration pad type (GSM100 t500mm pad)

・Weight:300kg

■Transportation

・Transportation truck: air-suspension vehicle

・Transportation distance:226km

■Measure

・Contents: Obtained the vibration level data of the upper and lower pallets while driving a truck

・Measuring device: 3-axis acceleration logger x 2 (Able to perform frequency analysis)

・Logger installation position : equipped one each on the upper Anti-Vibration plate and lower parts of Anti-Vibration palette itself.

・Range of measurement: ±6G

・Sensitivity: 200mV/G

■Analyzing parameter

・Window function: Hanning

・Number of lines: 2048

・Averaging: Addition average

・Sampling: 1000Hz

■Analysis result of vibration frequency while driving in high-speed

・Data of upper anti-vibration plate is in blue graph

・Data of lower non-anti-vibration palette is in green graph

--- Transport Test by Anti-Vibration Palette ---

※Below is the joint verification test with Nabeya co.,Ltd

■Shock-Resistance Test by Lifting Anti-Vibration Palette

【Impact Value G】

Without buffer material→13.5G

With Ether-based Polyurethane→3.0G

■Drop and impact test

【Impact Value G】

Without buffer material→10.1G

With Ether-based Polyurethane→0.8G

■Angle of Impact Test with Anti-Vibration Palette

【Impact Value G】

Without buffer material→ 15.4G

With Ether-based Polyurethane→4.2G

■Cantilever Drop Test with Anti-Vibration Palette

【Impact Value G】

Without buffer material→18.4G

With Ether-based Polyurethane→2.1G

■Pallet Jack Traveling with Anti-Vibration Palette

【Impact Value G】

Without buffer material→11.4G

With Ether-based Polyurethane→0.8G

■Forklift Driving Test with Anti-Vibration Palette

【Impact Value G】

Without buffer material→5.4G

With Ether-based Polyurethane→0.8G

■Shocking Results and Data Sheet of the Vibration & Shock Test Above

--- Anti-vibration Floor ---

■Floor Slab Anti-Vibration of the Same Specification As the Palette

・Covers the loading platform of trucks and demonstrate high-perform Anti-Vibration effect

・Covers JR containers’ floor and enable to control vibration while traveling

--- JR Container Vibration Transport Test ---

Today, the environmental problems such as CO2emissions due to global warming is drawing more attention in shifting to train transportation usage, however, the vibration during the cargo transportation makes the modal shift difficult for the products sensitive to vibration such as precision machines, therefore we have developed Anti-vibration floor to enhance the modal shift of JR container Anti-vibration transportation.

■Conducting a comparison test in transportation with Anti-vibration palettes, floor slab Anti-Vibration, and regular palettes.

・Round trip from Atsugi city in Kanagawa to Shimonoseki port in Yamaguchi

--- Patent-pending! Presenting the most effective approach for Anti-vibration transportation ---

We have applied for a patent on the technology of easily exchanging cushioning materials to achieve

the most appropriate Anti-Palette effect depending on the weight of the product.

・Design of Cushioning Materials: Nabeya co., LTD

・Design of Distribution Container : Musashi Trade Transport Co., Ltd.

Patent Application Number: Application2020-080730