We realize “zero-gravity transportation” to protect products from vibration and shock.

We propose export packaging that transports customer products to their destination more safely.

About ZERO G-Pallet

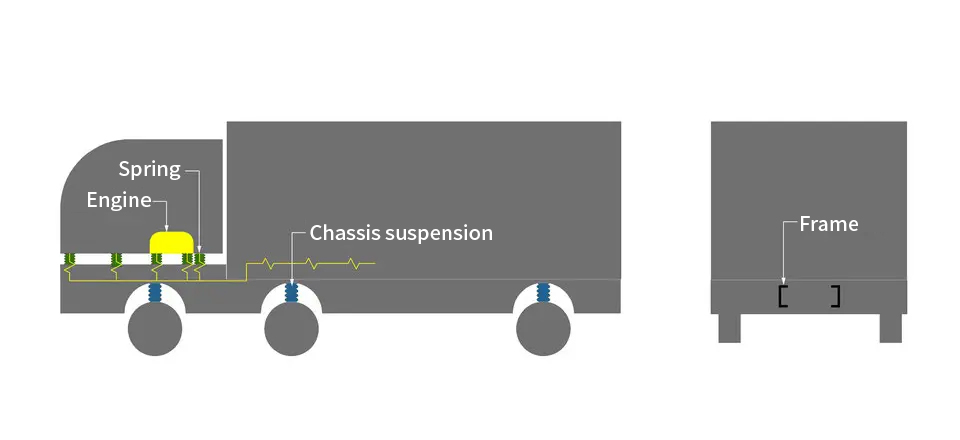

High-frequency vibrations greater than 20 Hz occur during truck, rail, ship, and air transportation. This high frequency cannot be eliminated by air suspension truck vehicles.

High frequencies can have a wide range of adverse effects on products, including solder cracks in substrates, poor plug contact, cracks in piping joints, and the loosening of bolts and nuts.

We have developed innovative vibration control products that cover a wide range of frequency bands and can be used in a variety of transportation modes.

The product is designed to be easily attached; however, it is made of durable materials that can withstand the harshest shipping environment.

This is an introductory video of the ZERO G series, designed for antivibration applications. Please consider this first.

Vibrations and shocks during transportation cannot be controlled using air suspension vehicles.

The engine constantly vibrates, which is transmitted to the frame, thereby affecting the cargo bed.

A chassis suspension can control the vibrations and shocks transmitted from the road surface; however, it cannot control the high-frequency vibrations transmitted from the engine to the cargo bed.

Examples of transportation scenarios subject to vibrations and shocks

- Road subsidence and bumps during trucking.

- Effects of product loading and unloading

- Railroad track switches and joints during rail transportation

- Landing and loading during air transport

- Forklift truck loading and unloading at container yards

- Loading and unloading in the packing plants

Examples of damage

- Damage to precision parts and cracks in product details

- Cracks in piping

- Peeling of printing

- Disconnected connectors

- Damage to fruits and vegetables, and cake collapse

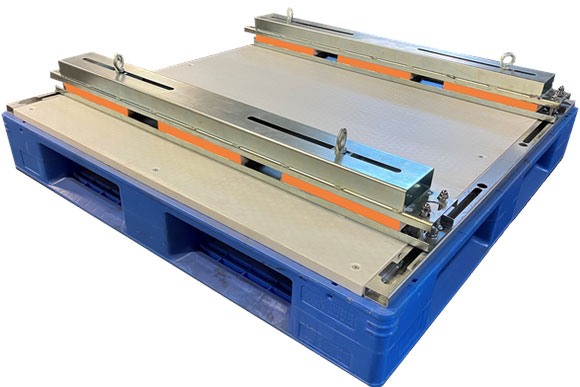

ZERO G-Pallet Features

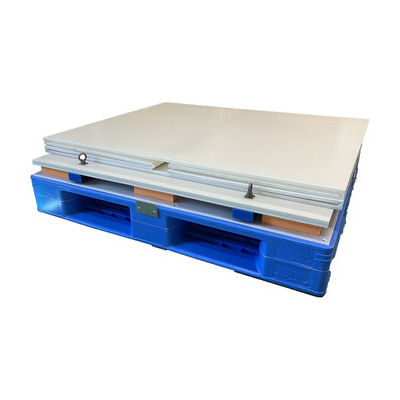

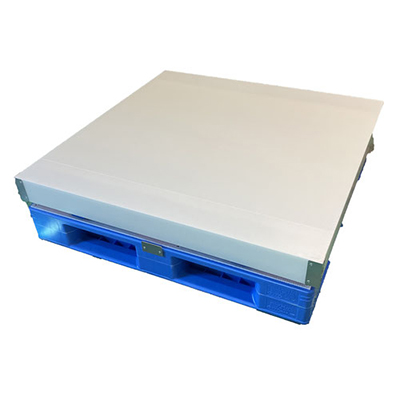

Made of resin pallet

- Superior vibration-isolation environment

- The vibration-insulating material is composed of an ether-based polyurethane foam with excellent vibration isolation and durability.

- Superior durability

- Customized sizes can be produced for various products.

- An appropriate cushioning material was selected based on the product weight to maintain a good vibration-isolation effect at all times.

Made of wood

- Superior vibration-isolation environment

- The vibration-insulating material is composed of an ether-based polyurethane foam with excellent vibration isolation and durability.

- An appropriate cushioning material is selected based on the product weight to maintain a good vibration-isolation effect at all times.

- Customized sizes can be produced for various products.

- It is suitable for one-way production because of its low cost.

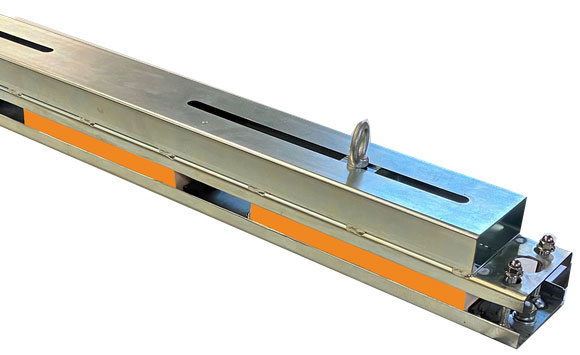

ZERO G-Sticks Features

Made of resin pallet

- Provides a superior antivibration environment for truck air suspension vehicles

- The vibration-insulating material is composed of an ether-based polyurethane foam with excellent vibration isolation and durability.

- Superior durability

- Customized sizes can be produced for various products.

- An appropriate cushioning material is selected based on the product weight to maintain a good vibration-isolation effect at all times.

- This can be converted into an antivibration pallet by attaching it to a sliding lock.

ZERO G-Box Features

Made of twin cone

- Resin pallets + twin cones to reduce box weight

- Durable twin cones are used for the sleeves and caps

- Easy installation and storage of sleeves and caps

- Efficient transportation loading and less space for stacking and storage

Features of ether-based foam polyurethane vibration isolators

- Supports continuous vibration damping and shock absorption

- Capability of damping from low-frequency vibrations

- Low creep (shape changes over time)

- More than 20 materials were used for different loads and vibration characteristics.

- Over 30 years of performance and reliability have been demonstrated.

- Excellent durability and long life

ZERO G-box

Patent application number: Application 2020-080730

Comparison of air suspensions and antivibration pellets

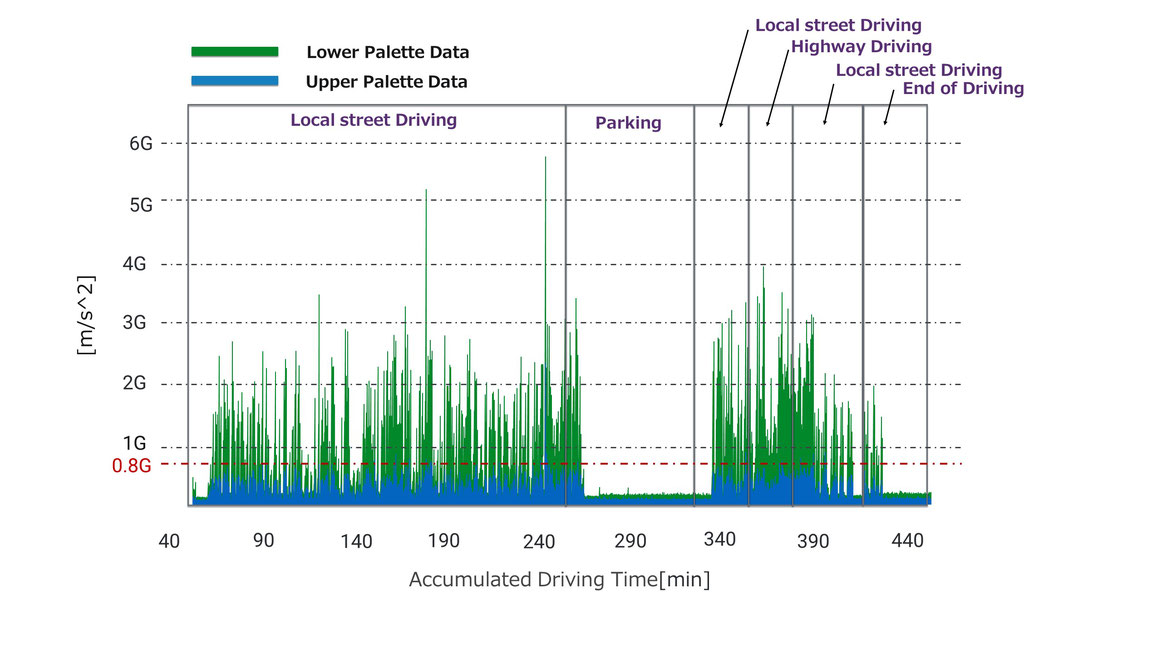

We conducted an actual driving test using an antivibration pallet placed on the cargo bed of an air-suspension vehicle.

It was confirmed that the high-frequency vibration of 21 Hz during the high-speed driving of air suspension vehicles could be sufficiently reduced, and that vibration and shock could be suppressed more than in air suspension vehicles.

An attenuation ratio approx. 91.4% (1/10 or less)

| Speed per hour | 90km/h | 80km/h | 70km/h |

|---|---|---|---|

| Engine RPM | 1410 | 1280 | 1110 |

| Cargo bed frequency for air suspension heavy duty vehicles | 24Hz | 21Hz | 18Hz |

| Frequency with antivibration pallet | 2.4Hz | 2.1Hz | 1.8Hz |

Driving test of actual vehicle to confirm antivibration effect

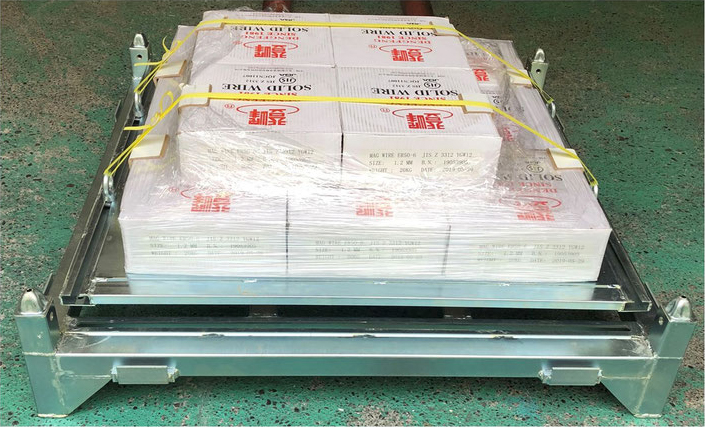

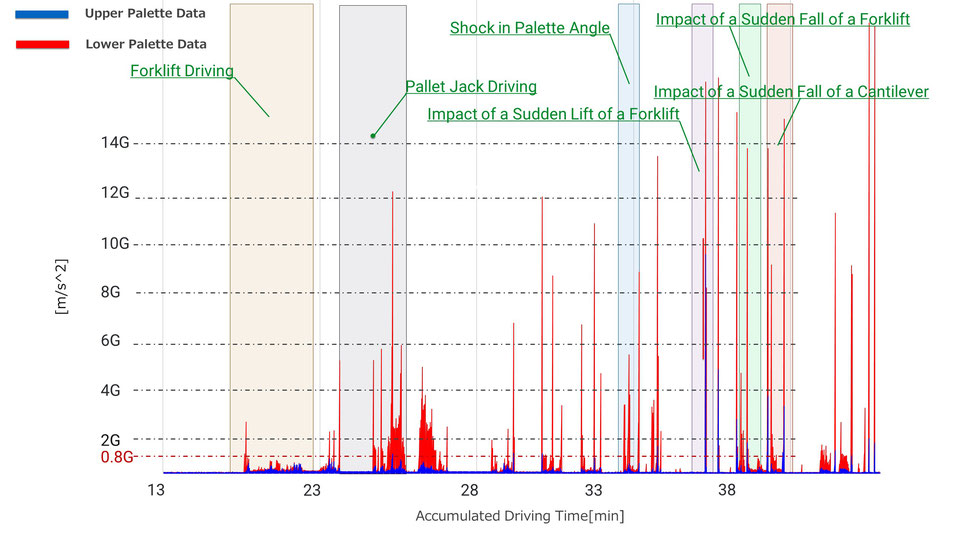

To verify the antivibration effect, an antivibration pallet (antivibration pad type) with a dummy weight was placed on a truck and driven to acquire vibration acceleration data for the lower (lower pallet) and upper (upper pallet) sides of the antivibration pallet.

| Test body | Pallet: 1100 x 1100 mm (steel) Antivibration pad type antivibration pallet (GSM100 t50mm pad) Weight: 300kg |

|---|---|

| Transportation | Transport truck: Air suspension vehicle Transport distance: 226 km |

| Measurements | Contents: Measuring acceleration of lower and upper pallets while the truck is running. Measuring equipment: 2 x 3-axis acceleration loggers (capable of frequency analysis). Logger installation position: 1 on the upper antivibration plate and 1 on the lower pallet body. Measurement range: ±6G Sensitivity: 200 mV/G |

| Analysis Parameters | Window function: Hanning Number of lines: 2048 Averaging: Additive averaging Sampling: 1000Hz |

Vibration frequency analysis results during highway driving.

The blue graph shows the data for the “ZERO-G Pallet.” The green graph is the data of “Air Suspension Vehicle Cargo Bed.”

We conclude that the ZERO-G Pallet can control the vibration to 0.8G or less in comparison with air suspension vehicles, which have a maximum vibration range of 5.8G or more, exceeding 1G.

In other words, the antivibration pallet exhibited superior antivibration performance.

Transportation tests with antivibration pellets

Lift impact test

| Impact G-value | |

|---|---|

| Without cushioning | 13.5G |

| Use of ether-based polyurethane foam | 3.0G |

Drop impact test

| Impact G-value | |

|---|---|

| Without cushioning | 10.1G |

| Use of ether-based polyurethane foam | 0.8G |

Angle impact test

| Impact G-value | |

|---|---|

| Without cushioning | 15.4G |

| Use of ether-based polyurethane foam | 2.9G |

Single-support drop test

| Impact G-value | |

|---|---|

| Without cushioning | 18.4G |

| Use of ether-based polyurethane foam | 2.1G |

Antivibration pallet hand-lift running test

| Impact G-value | |

|---|---|

| Without cushioning | 11.4G |

| Use of ether-based polyurethane foam | 0.8G |

Antivibration pallet forklift running test

| Impact G-value | |

|---|---|

| Without cushioning | 5.4G |

| Use of ether-based polyurethane foam | 0.8G |

Vibration and impact test results

Musashi’s Packaging Products

Pack with just a wrench

Antivibration pallet

Anti-vibration railroad container floors